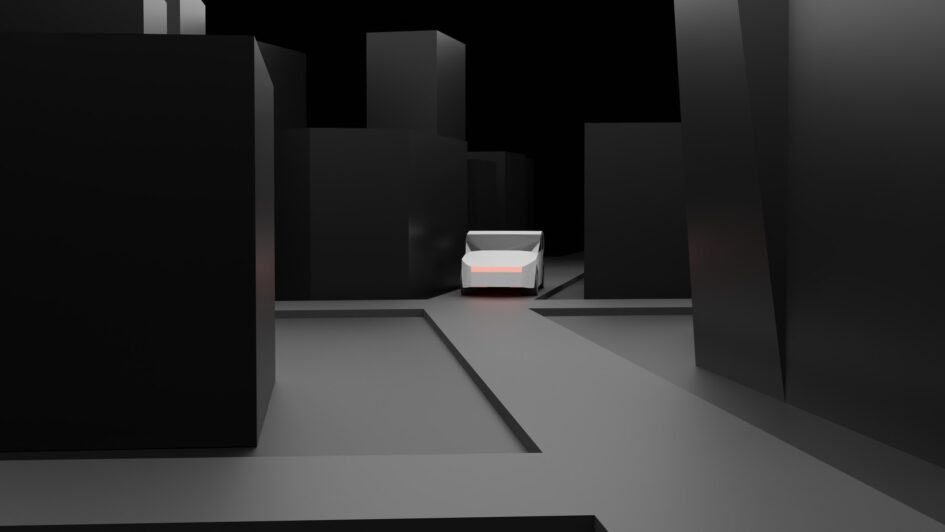

When the real world merges with mathematical models

In the world of automotive engineering, simulations are a central building block for development, testing and production. Today, three-dimensional digital twins (a virtualised model of processes and systems) to optimise factory and material flow planning. Car manufacturers use high performance computing (HPC) for augmented reality representations to develop and produce batteries or leverage real-time 4D simulations (3D +time) for the reaction training of driver assistance systems.

No longer just cars but rolling computers?

Virtual car models are considered highly complex systems, they must react in real time to simulated environmental conditions that are as close to reality as possible. The corresponding data normally comes from a wide variety of sources and gets adapted to the respective car model. This requires highly flexible HPC environments that are suitable for Big Data while minimising latency. For this purpose, many manufacturers today use cloud-native environments with containers and micro services to quickly provide test cases for different simulations. To prevent bottlenecks within the IT infrastructure of servers, workstations and storage the network needs to be high bandwidth and low latency. Since all the data derived from the simulations is highly sensitive, the IT environment also needs end-to-end protection against unauthorised access. These networks should be shielded according to the zero-trust principle.

Simulations are enabling new technologies

The current trends towards electric drives and autonomous driving are having a major impact on vehicle design and future configurations. Electric vehicles (EVs) need fewer components and subassemblies, while batteries must be as space-saving as possible yet have an extended range. In addition, the vehicles are becoming increasingly smart and the driver assistance systems make them more autonomous at the same time. These driver assistance systems need AI-based, self-learning systems that can link countless sensor data with empirical values to make driving safer.

For the changes required in production from petrol to EVs; the factory and material flow planning must be completely adjusted. To ensure that existing machines and systems can continue to run, manufacturers simulate digital twins. Using these simulations, they try to integrate the existing systems into the new manufacturing processes where appropriate.

Customised batteries

To ensure that batteries in EVs consume less space in the future and can be taken to market quickly, manufacturers today rely on increasingly complex simulation techniques. Volkswagen (VW), for example, entered a cooperation with Google in 2017 to simulate the chemical structure of industry-relevant molecules on a quantum computer. VW scientists at the CODE Lab in San Francisco want to use this as a basis to simulate the chemical structure of a complete battery for EVs on a quantum computer. What they want to achieve is the delivery of a configurable chemical blueprint directly to production in order to manufacture customised batteries. With the help of these simulations, VW started to explore the potential of quantum computers. Last year VW announced in the press to team up with their California based battery development partner Quantumscape. From 2025 onwards, they want to start manufacturing corresponding solid-state batteries in Salzgitter. In addition, VW is using quantum computing for AI-based machine learning processes to develop partially and highly automated driving functions.

Deep Learning needs data, data, and data – but from real test drives, please!

Tesla is also investing in a couple of super computers to gain enough compute power for the Deep Learning (DL) of its auto pilot. Experts assume that the latest DL technologies will no longer work with algorithms but will be data-driven instead. With that said, developers would need to adapt data sets in the future. To train such decision-making algorithms for autonomously driving cars, the neural networks need sufficient data from real test drives to have an adequate behavioural pattern stored for practically every possible scenario. Thus, the algorithms are no longer based on image files, but vectors.

For data collection Tesla uses a fleet of 1000 vehicles with eight cameras each. When these cameras are in operation for one hour, they take 36 frames per second of the environment. This adds up to a total of over one billion frames and several thousand objects. Coming on top are countless sensor data, e.g. from speed and rpm to measuring of GPS data, which are then collected in the Tesla supercomputer and labelled with metadata. This creates 4D vector data.

Labelling, for example, enables the realistic reproduction of the road, masking effects, and kinematics via further camera recordings of the vehicle or other vehicles at the same location. To ensure that DL also considers scenarios occurring with extremely little likelihood, these are simulated in the 4D neural networks. This is how Tesla trains its autopilot in a simulated environment that is vector based and therefore reflects reality as realistically as possible. The goal is that an autopilot should be able to seamlessly transfer its learnings into subsequent driving operations to be prepared for all conceivable incidents.

Thank you, Augmented Reality, for making communication of connected vehicles secure!

Similar simulations are also necessary for testing driver assistance and multimedia systems. Vehicles are equipped with more and more communication systems that must interact reliably and should not interfere with each other under any circumstances. To meet this requirement, a three-dimensional vectorial vehicle model is generated containing the individual transmission sources with its antenna characteristics. This enables developers to analyse the transmission behaviour in the vehicle in a fully simulated environment and, for example, to optimise mounting conditions. In addition, the transmission and reception behaviour of a device can be examined in a simulated high-frequency environment with other devices in the vehicle as well as different outdoor environments. Here, too, the various traffic scenarios are partly based on recorded test drives, which can be adapted as required. This is how communication systems can be coordinated and optimally placed at an early stage.

This means that the new drive technology and vehicle networking will play a role in determining the design of future vehicles. The implementation is initially carried out via complex simulations starting with the first design study, through all development and test phases to production. These simulations are based on a huge data pool from which the required vector data is generated.

What about Storage specifications and Augmented Reality?

The storage solution of choice in a HPC environment must write all captured sensor and video data including the metadata lossless and with the lowest possible latency. In return, the respective data for a 3D or even 4D simulation must be read with as little latency as possible to act realistically. The optimal storage solution for this use case scenario has a high-performance cache for the simulations and sufficient hard disk space for the various scenarios, configurations and test runs.